Die Making

Overview: Forming Steel Rule Dies into Different Shapes for the Die Cutting Process

What is Die Making?

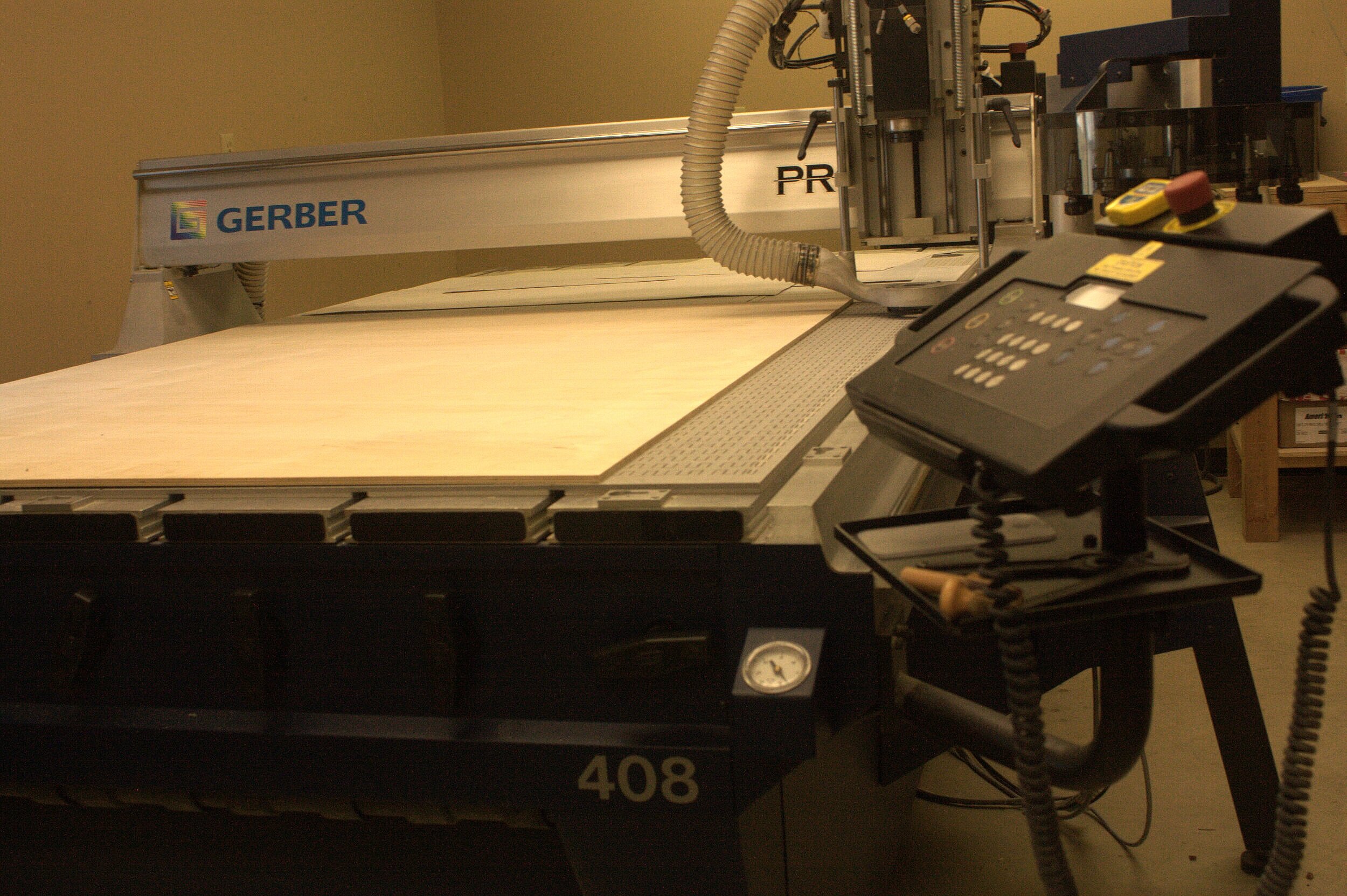

Die making is the process of preparing the metal cut out to get a print piece into a specific shape. Essentially the die making process must be completed before the die cutting process can happen. The die making process consists of three main components: the die base, the steel rule die, and the rubber/foam ejection. Starting with a bendable metal strip known as a steel rule, the sharp cutting die is formed into a desired shape. The steel rule can vary in height, thickness, and overall shape of the cutting edge depending on the print material. A laser is then used to cut a slot in the dieboard to insert the steel rule. After, a foam or rubber ejection is added along the steel rule to help push the cut-outs from the tool for removal. It’s then inserted into a die cutting machine to cut a print piece into its desired shape.

At Phillips, we manufacture our own steel rule dies using state-of-the-art CAD design software and hardware. We also provide design services and sample construction to assist in creating your unique concept.

Die Making Considerations

The thickness and compressibility of the print material needs to be considered to better determine the steel rule die’s thickness and cutting-edge length for an effective cut.

The intricacy of the design is intercepted by CAD design software to make the steel rule die for the print design cut-out. The software then takes the producibility, features, and functionality into consideration. As a result, some adjustments may need to take place.

The typical timetable for steel rule die making is anywhere from one to three days. This can make it difficult to get tight deadlines out on time, so be sure to work that into the project timeline.

Benefits of Die Making

The presses in die making operate at high speeds, which in turn produces faster production times.

When a die needs a tweak, changes can be made the same day with Phillips for extra flexibility and convenience.

Phillips provides in-house die making. Other print finishers outsource die making, which would require a two-to-three-day deadline project extension.

Die Making Capabilities

Steel rule dies manufactured in house

CAD design services & sample making

“I have used many other print finishing partners, but Phillips is the most trustworthy and my go-to for honest, quality work. I never feel like I am second rate.”

Project Samples

This Axe Body Spray promotional, collapsible box utilized a glue detection system for straight inline gluing. As an overflow project, Phillips shipped the service flat to save on space and time.

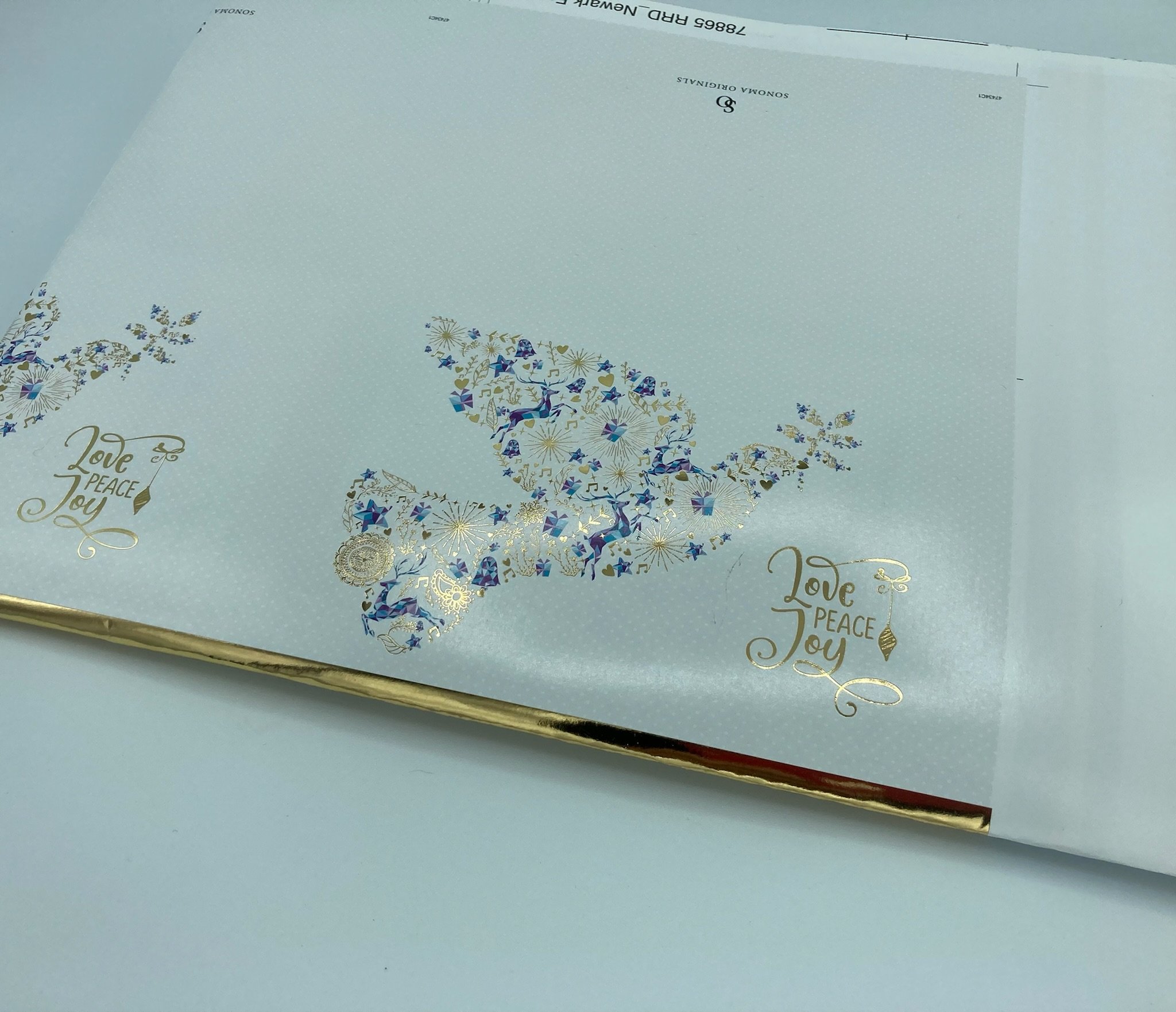

This holiday greeting card was foil stamped and die cut to add an eye-catching finishing touch. It was folded into fours and carton packaged for shipment.

This Hershey's Happy Holiday Chocolate Box Sleeves include foil stamping as an attention-grabbing feature on store shelves. It was also die cut, trimmed, and taped for added finishes.

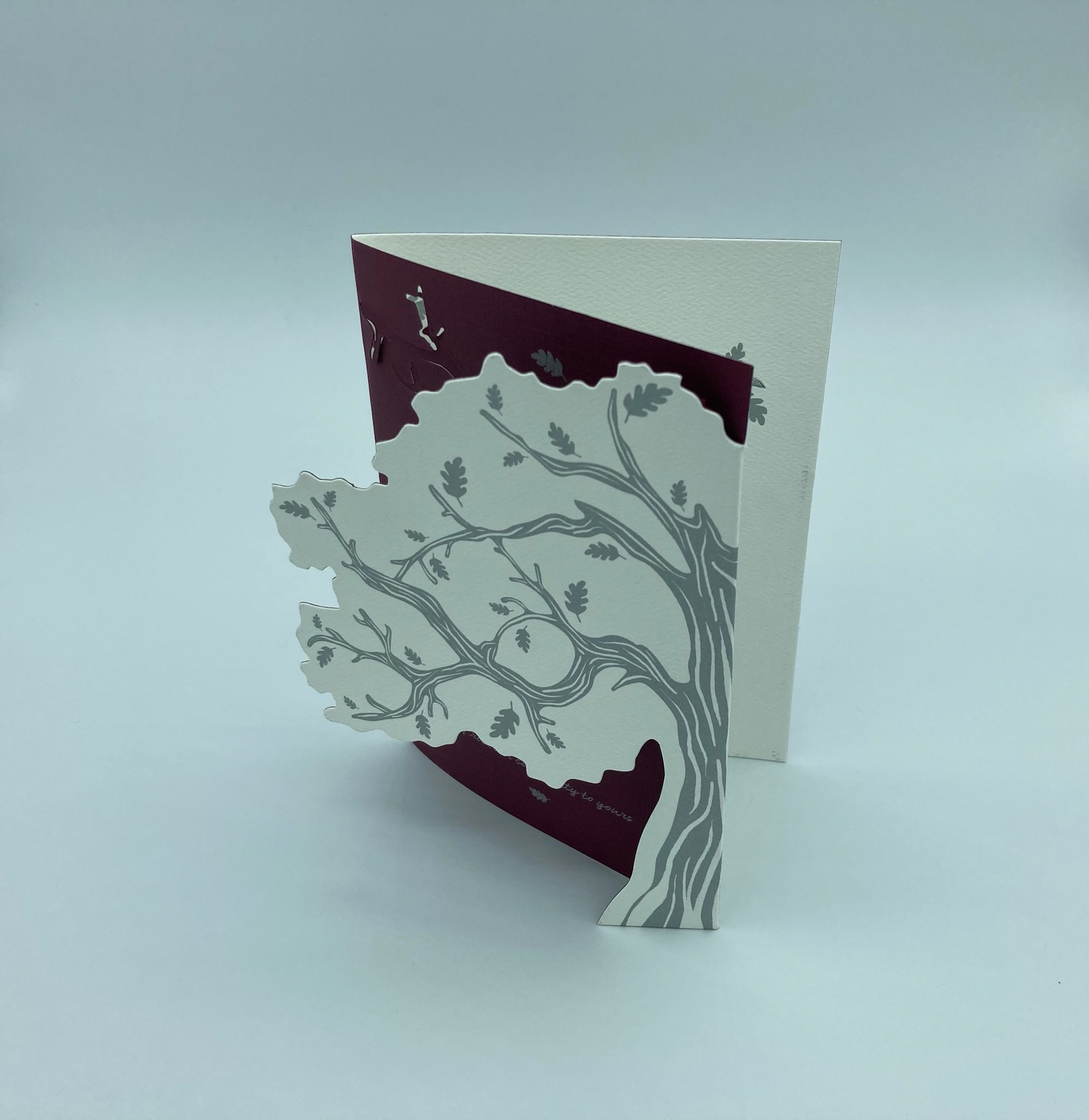

This company holiday greeting card was die cut and trimmed to get the unique shape of each tree branch. Opening the tri-fold, mounting was added to give an added layer of depth for recipients.

This Hertz Tri-Fold Tesla Promotion Mailer was a very intricate piece with die cuts to the outside for the arrow point panels and glued pockets for quick info pull-out tabs.

This Vitus Deodorant Box was stripped, trimmed, glued, and folded to hold 30 packets of deodorant samples.

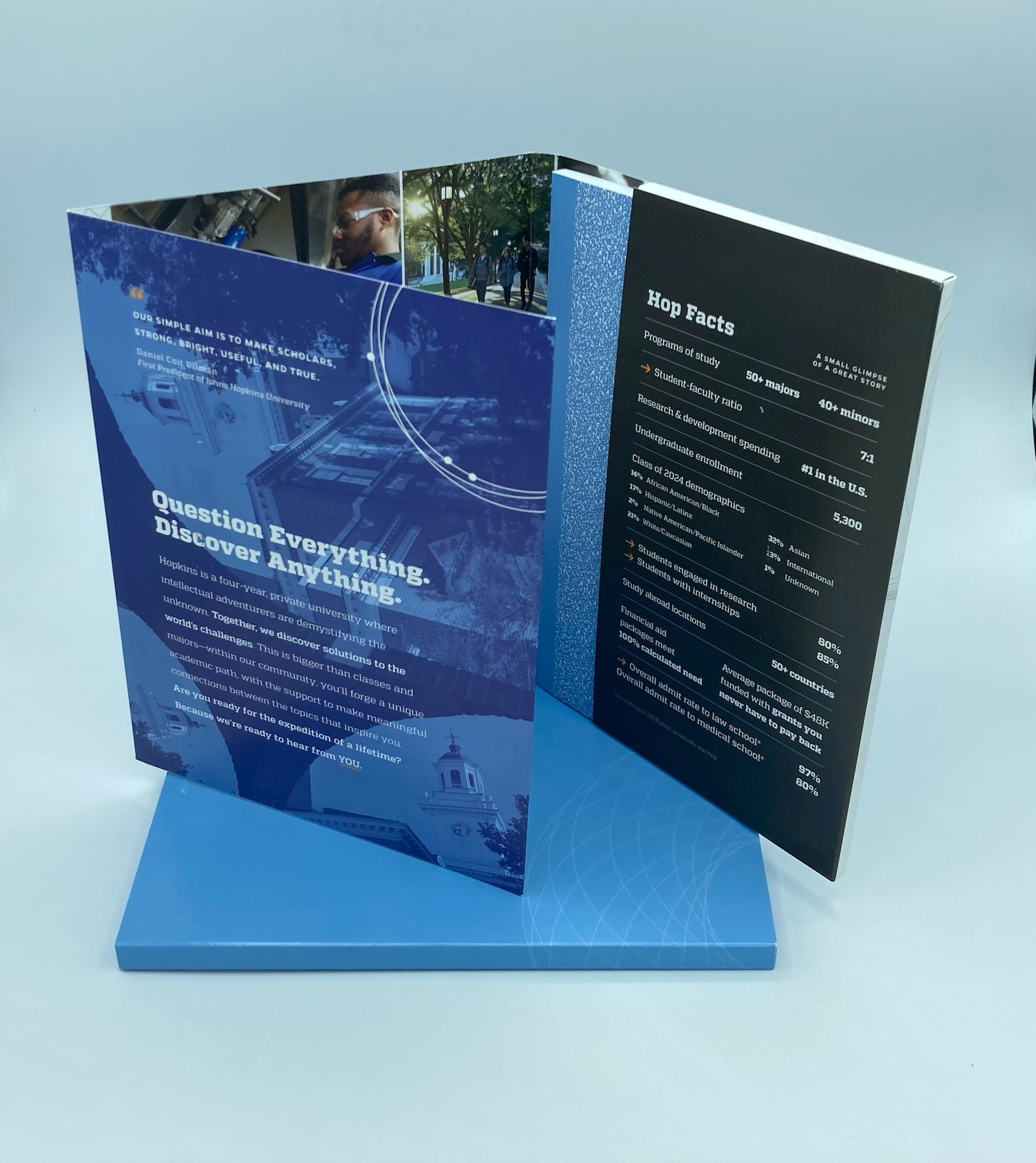

This John Hopkins Discover Kit included: a folder, journal, and shipment box that was sent to prospective students. This job included just about every type of finishing service. The folder itself was double glued and automated through a sprint unit to ensure everything would be held together in tact.

These Reese's Holiday Paper Ornament cutouts were die cut to get the round shape of the ornament. They were hand folded and attached to Reese's candies with a recipe inside.

This John Hopkins Discover Mailer Box was part of a larger kitting job. It includes a zip strip perforation to make it easier for prospective students to open the package.

This Pennsylvania Lottery Box was held at various service stations with pamphlets to promote the lottery. It was created as a crash lock box to snap into place so it's more sturdy when it stands up.

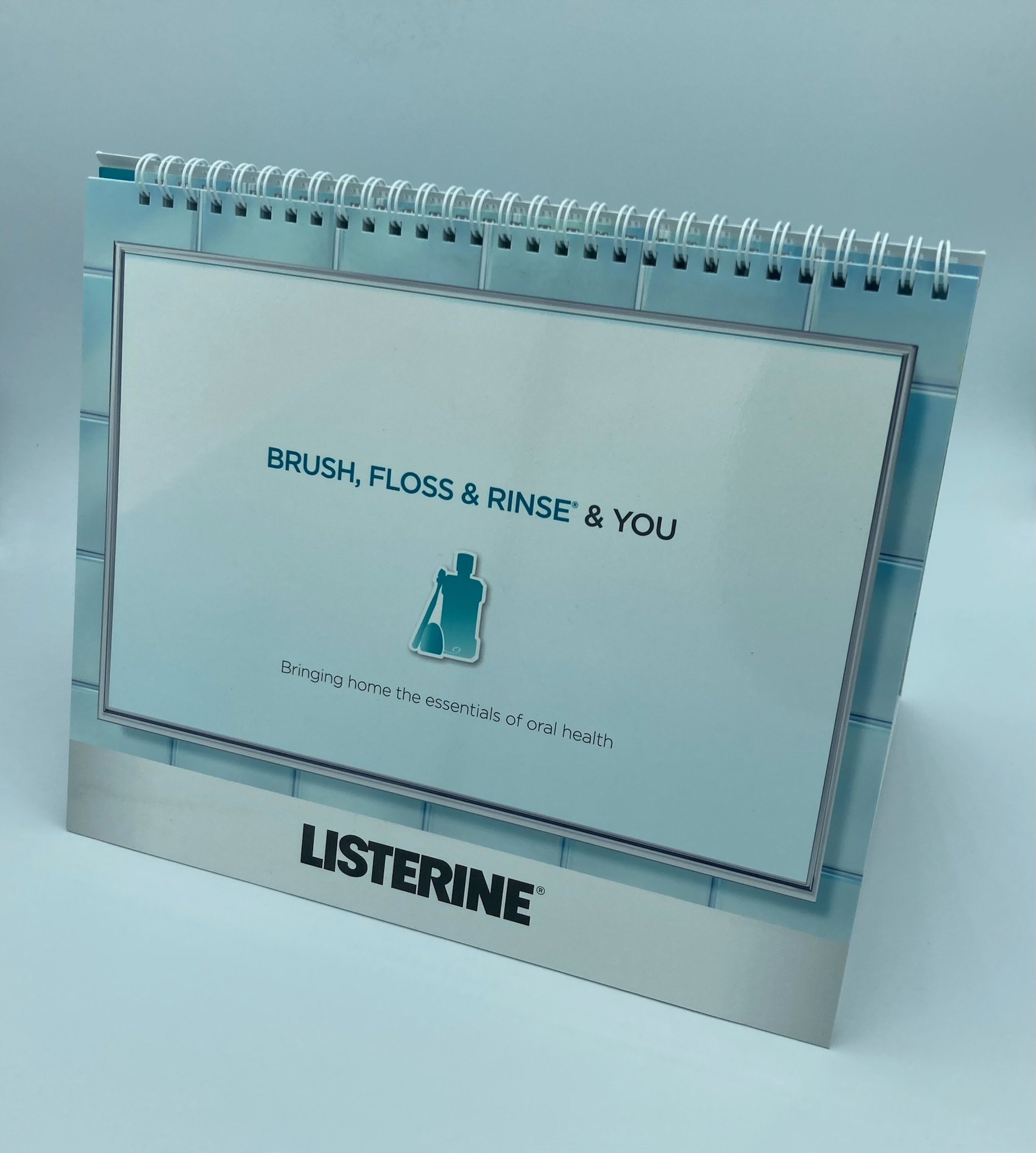

This Listerine Oral Health Wire-O Bound Flip Book is used for product promotional purposes in the waiting rooms of dentists' offices. Three die cuts were created for the outer cover, inner tabs, and back cover. It was collated, glued, folded, and punched to get the finished look.

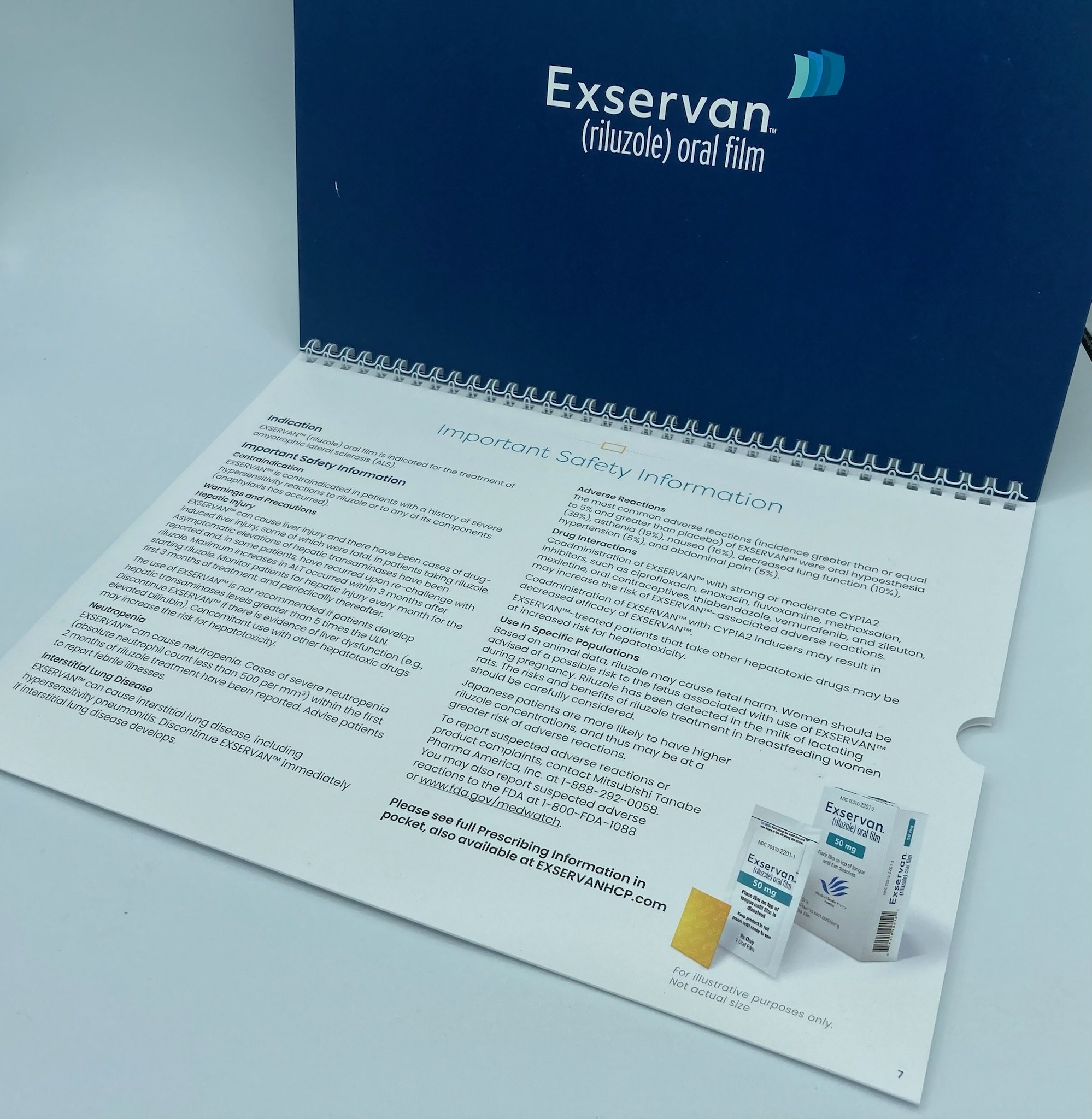

This Exservan Oral Film Wire-O Bound Flip Book serves as an informational piece to ALS patients where swallowing medications is difficult. It promotes the film form instead of the pill form. This piece is great for those who would use it for a presentation or in sales.

This Live Action Box is a promotional event piece that's mounted and glued to corrugated cardboard for added strength and durability. It was used to hold other pieces and materials as an event kit.

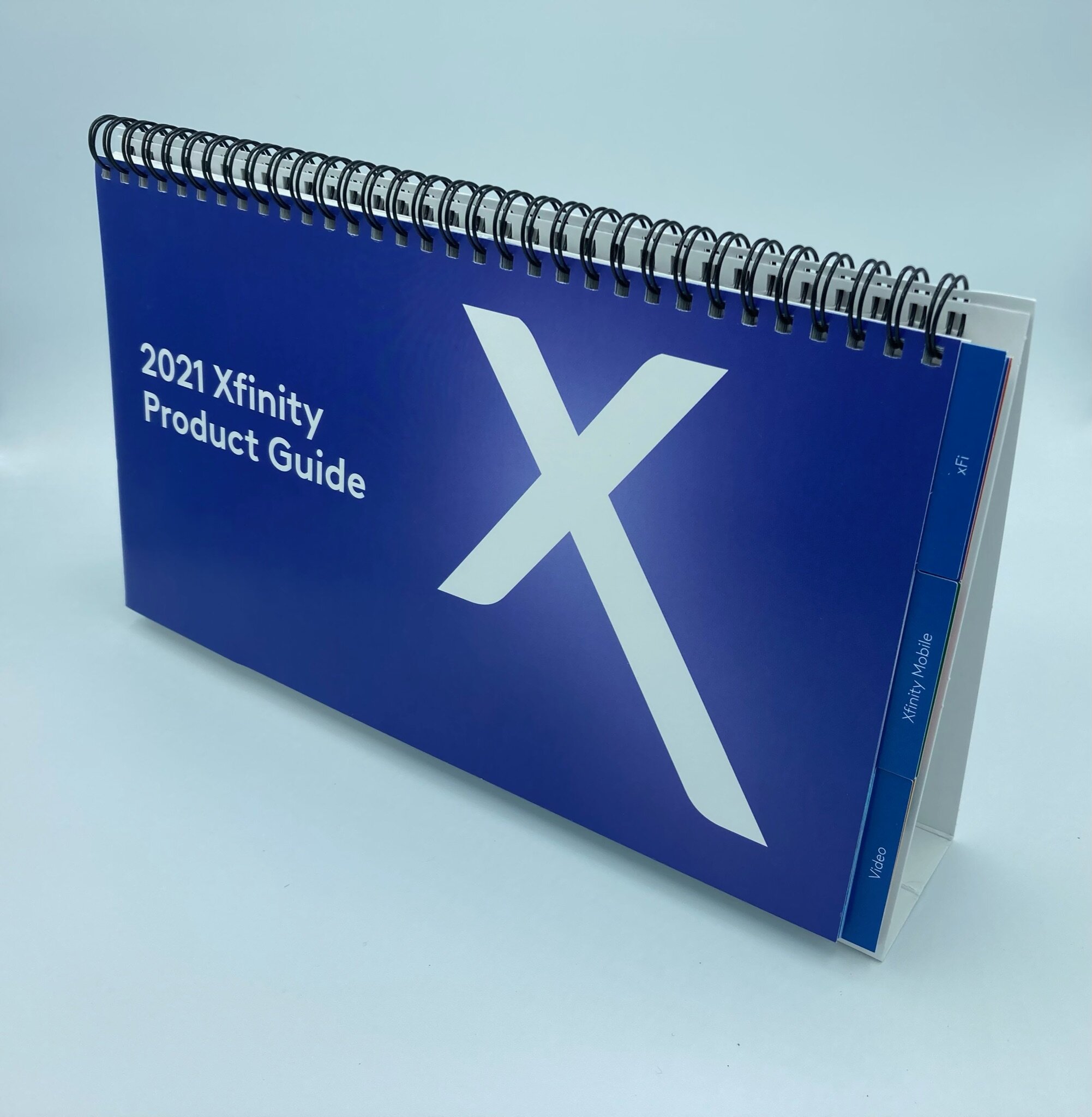

This Wire-O Bound Product Guide was carefully collated into different sections making it easy to flip through the different organizational tabs based on Xfinity's video, mobile, and Xfi products. This is a great option for any business to showcase its product line.

This Garden of Life Supplement crash lockbox makes it easy to package any product for consumer use. Stripping, die making, and double face tape was applied to give this box a precise look and keep everything in tact.

This VOD Diagnostic Criteria Card was created all in one piece with a small fold-out section and double glued panel to lay on top. Using fugitive glue, it was fed through a multi-feeder to attach the risk factor card, making it easier for patients to spot VOD symptoms.

This multi-dimensional USPS Small Business Folder was hand folded and glued for a unique look. It includes fold outside descriptions and a deep pocket folder to house additional printouts and material.

This Bausch + Lomb Contact Recycling cut out was a specialty die cut piece used in a larger promotional project. It was shrink-wrapped in plastic film in packs of 25 for easy disbursement.

This United Airlines Credit Card Brochure was die cut in a cylinder press due to the use of light paper and the number of folds. It uniquely stands out from other brochures due to the embio folder, perforations, and remoist glue to lick and seal to send back the accepted credit card offer.

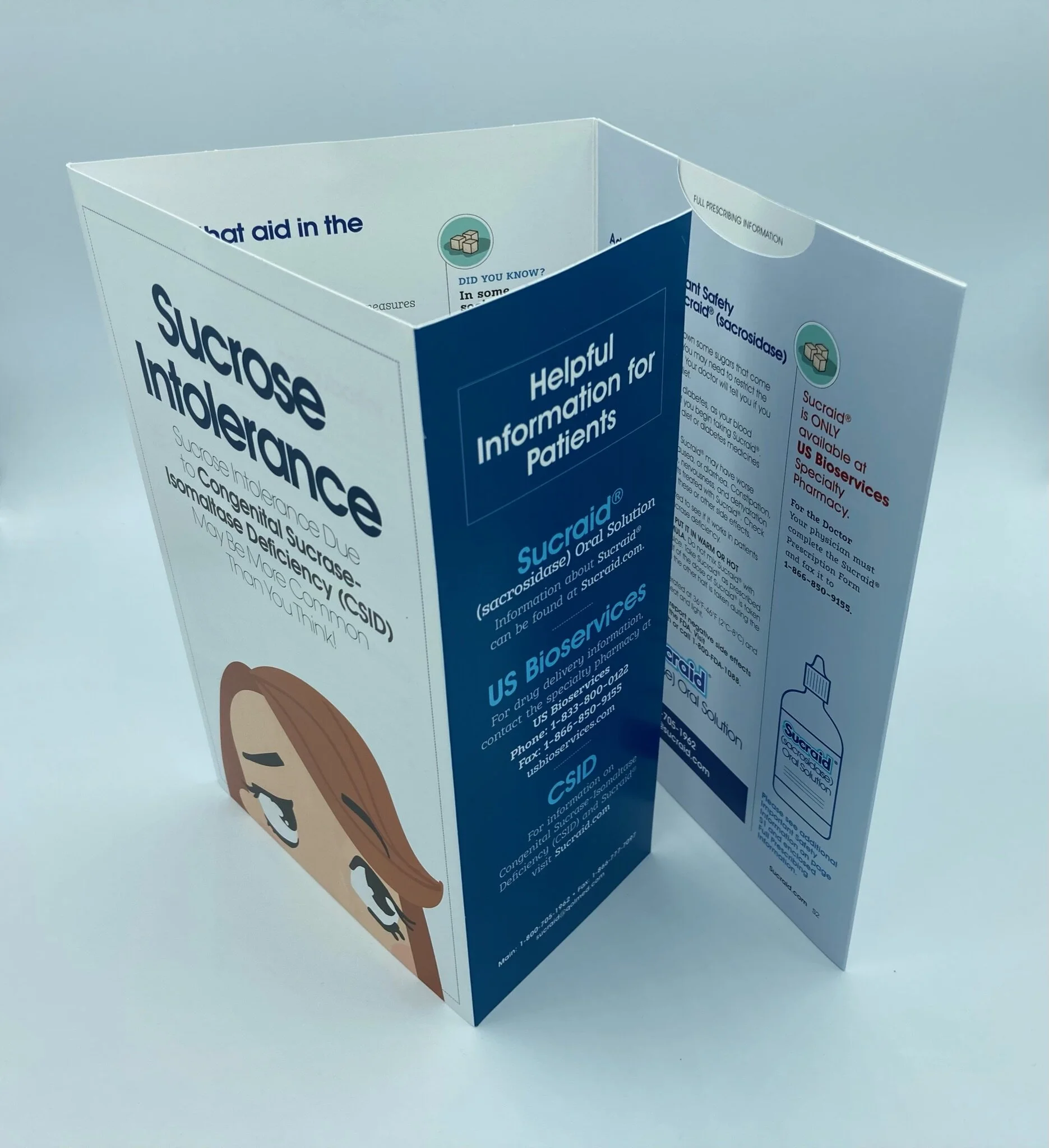

This long, narrow Sucrose Intolerance Brochure was glued and folded with a final fold. Within the brochure, there's a thumb cut to pull out additional prescription information. The mail panel was also completed in-house to streamline the distribution process so it could go straight to the post office and mailed to homes.

This Global Atlantic Capacity Folder includes more than one crease in the pocket to hold lots of material. It was made on a sprint unit that forms the tabs with automatic glue. Handwork was used at the end to compile the one sheeters in the pockets

This Vaxelis Vaccine Brochure was saddle-stitched on a Heidelburg stitcher with an automatic insert for personal information. It was then shrink-wrapped for easy distribution.

This McDaniel College Homecoming Booklet features an eyelet and die-cut to reveal the spinning window. Perfect hand alignment was also utilized to stitch the short page on the inside of the booklet.

This dual invitation and capacity folder has an elevated look with foil stamping and embossing that was completed in just one pass. It’s sturdy and has an elevated look compared to that of an ordinary folder. The Phillips Graphic team was time-sensitive with this quick turnover project and completed it with ample time.

This 8 inch round Ben Franklin paper mint has high-end gold foil and embossing features, making it a great addition to any brochure, folder, or mailer project.

This 1/2 inch thick, collated Wire-O bound Expo-Guide includes a 3:1 punching for the bind. The sheet in the middle of the book folds out to better illustrate the convention layout, while still maintaining the guide's width parameters. It’s a great interactive piece for any business marketing.

This high-value foil stamped and embossed invitation folds out to reveal a pocket with a hand inserted card. Individual and variable stocking delivery was included. It’s a great alternative if you’re looking to level up your event.

This uniquely shaped Lancaster Restaurant Menu includes a tension grommet drilled for a fan effect, for a fun and clean look.

This counter brochure stand is mounted on a chipboard for maximum sturdiness. Set up as a monthly reoccurring order, these stands are shrinkwrapped for convenient delivery.

This engaging mailer includes a hand-glued pop-up hydraulic shock tube when the piece is opened. Design assistance and mock-ups were also included before the piece was sent to print.